As I was putting my cornhole boards together I was also thinking about ways help other people build their own. I still plan on making a downloadable cut sheet and CNC route file for other DIYers to follow, but first I want to make sure the design well thought out. To fine tune both the design and the instructions, I'm recreating the board as a digital model.This also gave me an excuse to play around with making diagrams and renderings with Rhino.

Lately, I've been enjoying a book called "Invention by Design" by Henry Petroski. It's been a refreshing alternative take on the process of design as practiced by engineers (as opposed to architects/designers.) One chapter describes engineering as the art of anticipating failure and mitigating it's effects. While building the modeling, I found one such possibility of failure in my original cornhole design at the pivot point of the legs.

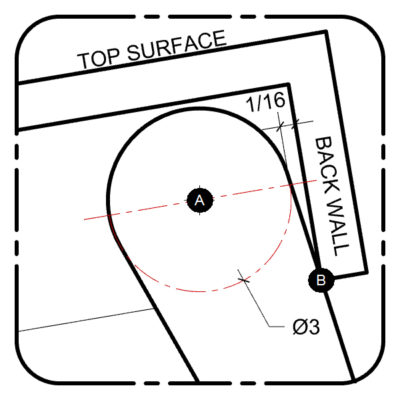

In the original design, I'd offset the pivot point (A) from the back wall so that the leg wouldn't rub against that wall as it pivoted. The angle of the leg would be maintained by the location of the pivot point (A) and the contact point between the leg and back wall (B). I saw foresaw 2 potential issues with this: First, with the point of contact being on a corner, that corner would wear down more easily and make the angle inconsistent. Second, if someone were to stand on the board (a likely scenario among drinking bag-tossers) the outward force of the weight-supporting leg would act as a pry bar on the back wall. With the contact point (B) being all the way at the bottom of the back wall, the wall would need to resist a much higher outward prying force.

In the original design, I'd offset the pivot point (A) from the back wall so that the leg wouldn't rub against that wall as it pivoted. The angle of the leg would be maintained by the location of the pivot point (A) and the contact point between the leg and back wall (B). I saw foresaw 2 potential issues with this: First, with the point of contact being on a corner, that corner would wear down more easily and make the angle inconsistent. Second, if someone were to stand on the board (a likely scenario among drinking bag-tossers) the outward force of the weight-supporting leg would act as a pry bar on the back wall. With the contact point (B) being all the way at the bottom of the back wall, the wall would need to resist a much higher outward prying force.

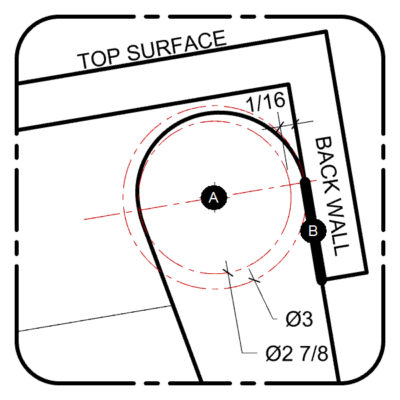

A modified solution tackles both of these issues, while still allowing the leg some room to pivot without rubbing. I spread the contact area (B) along the back wall to minimize wear and reduce the prying force. Then, in order to maintain the pivoting space, I offset a smaller circle about 1/16" from the outer circle to create the non-contacting edges of the leg. I wanted to maintain the pure, teardrop shape of the leg, so rather than adding stepped transition from outer circle to inner, I opted to ease that transition with a half spiral.

A modified solution tackles both of these issues, while still allowing the leg some room to pivot without rubbing. I spread the contact area (B) along the back wall to minimize wear and reduce the prying force. Then, in order to maintain the pivoting space, I offset a smaller circle about 1/16" from the outer circle to create the non-contacting edges of the leg. I wanted to maintain the pure, teardrop shape of the leg, so rather than adding stepped transition from outer circle to inner, I opted to ease that transition with a half spiral.

I'm not sure if this quite counts as "engineering," but it is satisfying to solve these kinds of problems and continue making small improvements on my design.