The final room in the build-out couldn't wait any longer. I'd built the scaffolding, we had the other rooms far enough along; it was time to enclose the loft.

Day 1

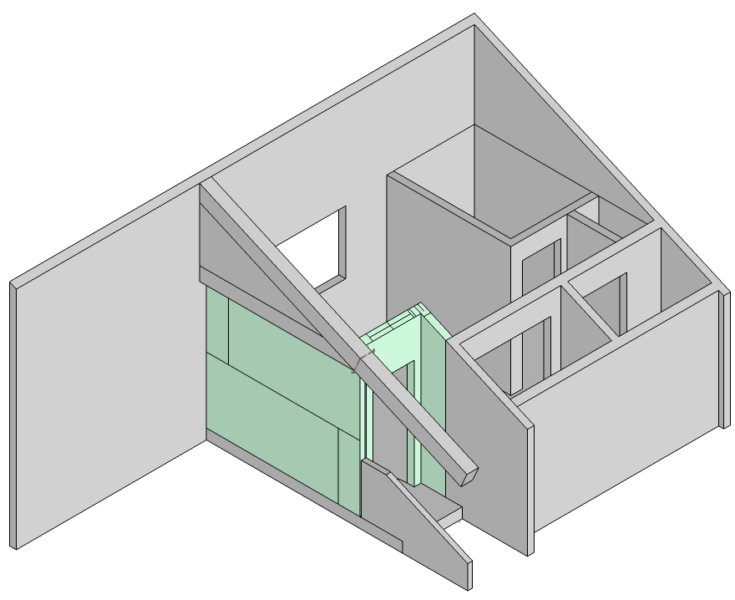

Jump to Day 2 or Day 3 This balcony space was a great vantage point to look out over the main space, but because of this it didn't have the level of privacy needed to be a bedroom.Our plan was to build a wall at the edge of the balcony so that it could die into the beam above. The wall would then turn with a door in front of the stair, and end in the existing wall. The door had to open inward because of the staircase, which also necessitated we create a balcony at the top (at the expense of a little room space.) All in all, the design was straightforward. It was the construction that most concerned us. While this room required the fewest walls, the slope of the ceiling, the loft ledge, and the beam above made this room the most daunting of the three.

This balcony space was a great vantage point to look out over the main space, but because of this it didn't have the level of privacy needed to be a bedroom.Our plan was to build a wall at the edge of the balcony so that it could die into the beam above. The wall would then turn with a door in front of the stair, and end in the existing wall. The door had to open inward because of the staircase, which also necessitated we create a balcony at the top (at the expense of a little room space.) All in all, the design was straightforward. It was the construction that most concerned us. While this room required the fewest walls, the slope of the ceiling, the loft ledge, and the beam above made this room the most daunting of the three.

First things first, there was a handrail here that had to go. It was actually alarmingly easy to dismantle as the whole thing was basically held in place with about 4 finish nails. Some work with the saws-all and we had the guardrail removed, and started pulling out these copper pipe balusters. I'm excited to come up with something cool to do with those.

First things first, there was a handrail here that had to go. It was actually alarmingly easy to dismantle as the whole thing was basically held in place with about 4 finish nails. Some work with the saws-all and we had the guardrail removed, and started pulling out these copper pipe balusters. I'm excited to come up with something cool to do with those.

The framing process was fairly well documented in my other posts, but there were a couple (many) specific challenges here that we had to meet head on. Firstly, our wall followed the angle of the ceiling where it turned down. We made sure that one of the studs was located right at that joint to make sure it helped navigate the angle.

The framing process was fairly well documented in my other posts, but there were a couple (many) specific challenges here that we had to meet head on. Firstly, our wall followed the angle of the ceiling where it turned down. We made sure that one of the studs was located right at that joint to make sure it helped navigate the angle.

We also needed to align the final face of the finished wall with the existing wall and the face of the exposed beam. To make sure we located it right, I held a spare scrap of 5/8" drywall up to the studs and pushed/pulled it into alignment.

We also needed to align the final face of the finished wall with the existing wall and the face of the exposed beam. To make sure we located it right, I held a spare scrap of 5/8" drywall up to the studs and pushed/pulled it into alignment.

Finally, we flat framed the whole wall. It had to die into the beam above, but the total thickness of a regular framed wall would have been too thick and parts of the wall would have stuck out. I must say, flat framing a tilt up wall was quite a challenge. Mostly, the difficulty was in not splitting the wood, and I found that pre-drilling the nail holes helped tremendously.

Day 2

We started day 2 by finishing the framing. Although we were done with the seemingly dangerous portion of work near the edge of the loft, there were still some sufficiently complex walls remaining. The tilt-up wall with the door had a short section below the beam that would meet up with the flat-framed wall. The door position was based on the need to have a single stud (the king) Runing all the way up to the ceiling. When we realized how thin the roof/ceiling assembly was likely to be, we knew we couldn't nail directly into it, this meant every upper level anchor point, like that king stud the was extra important.

We started day 2 by finishing the framing. Although we were done with the seemingly dangerous portion of work near the edge of the loft, there were still some sufficiently complex walls remaining. The tilt-up wall with the door had a short section below the beam that would meet up with the flat-framed wall. The door position was based on the need to have a single stud (the king) Runing all the way up to the ceiling. When we realized how thin the roof/ceiling assembly was likely to be, we knew we couldn't nail directly into it, this meant every upper level anchor point, like that king stud the was extra important.

We also added a piece of wood trim to the top of the wall above the door. We needed to hide a connection to the adjacent beam on the other side of the door, but also wanted an tidy way to end the drywall. Since all of our lumber was pine for studs we needed a piece that would actually match the look of the house, and what better way than to use something that was already part of the house! The handrail that we removed the day before fit the bill perfectly. So we installed that as what is likely the fattest piece of trim ever!

After we got all the framing finished, we tackled what we thought would be the most difficult part of the whole build-out: Hanging the exterior drywall. First, we had to snake a full sheet through the narrow gaps between the studs. Then we had to set the bottom piece of drywall on the narrow ledge (we decided it would be easier to frame this wall from the bottom.) A metal brace was still there from the handrail, so we used that to help us hold the bottom sheet in place. The top piece proved a bit more difficult. We had to move it on and off the scaffolding 3 times to rasp and re-rasp the cut end to get it to fit. Since we didn't have room for the stilts we let the lower sheet of drywall hold the top in place, but there was a scary moment or two, where the sheet nearly fell out of place and down through through the gap with the scaffold. With great persistence, we prevailed in the end!... and promptly called it a day.

After we got all the framing finished, we tackled what we thought would be the most difficult part of the whole build-out: Hanging the exterior drywall. First, we had to snake a full sheet through the narrow gaps between the studs. Then we had to set the bottom piece of drywall on the narrow ledge (we decided it would be easier to frame this wall from the bottom.) A metal brace was still there from the handrail, so we used that to help us hold the bottom sheet in place. The top piece proved a bit more difficult. We had to move it on and off the scaffolding 3 times to rasp and re-rasp the cut end to get it to fit. Since we didn't have room for the stilts we let the lower sheet of drywall hold the top in place, but there was a scary moment or two, where the sheet nearly fell out of place and down through through the gap with the scaffold. With great persistence, we prevailed in the end!... and promptly called it a day.

Day 3

The third and final day was something of a scramble to get finished. The roommate staying in the loft had traveled for the three day weekend, but was returning later that afternoon. I didn't get a chance to take any progress photos as we hung all the remaining drywall, but managed to grab some at the end. In addition to hanging the drywall, I installed the third and final door. Considering how complicated the whole loft construction was destined to be, we were quite pleased at the relative lack of issues.

Carpenters tip from L.D. Kinnaird – blunt the point of a nail by giving it a hammer stroke and this will reduce the chances of splitting wood. A sharp nail wedges through the wood, while a slightly more blunt tip tears through.